As I type on this keyboard right now, let's take a journey through the fascinating process of its creation!

What I aimed for when building the keyboard was a deep key sound and maximum flex, so when you press the keyboard, the PCB flexes downwards slightly, preventing your fingers from hurting after prolonged usage.

There are 7 main components that are modded in this keyboard, from bottom to top:

- The case

- The polyfill layer

- The tape mod layer

- The PCB

- The plate

- The switches

- The keycaps and sound control knob

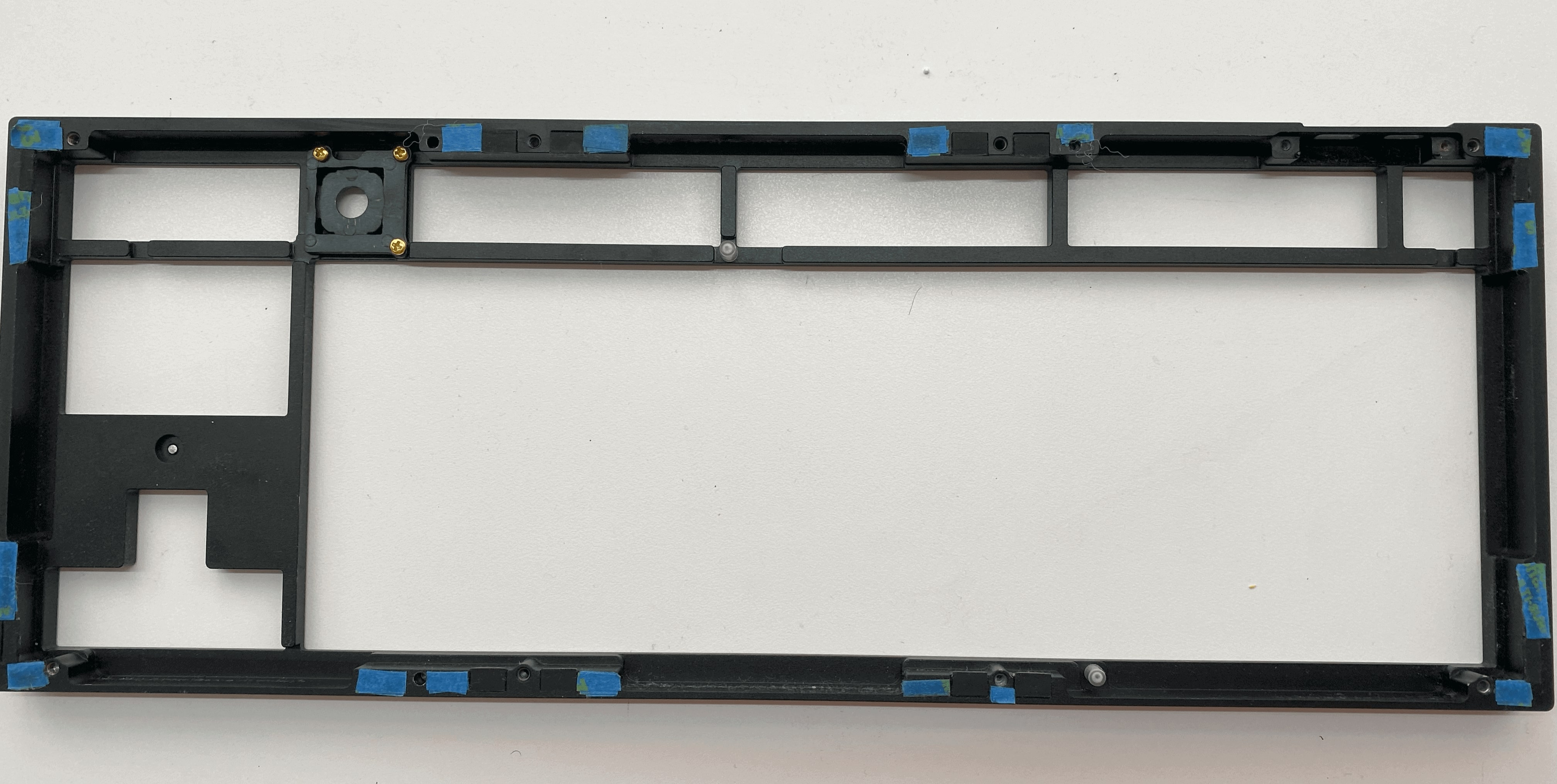

The case:

- The case is made of aluminum.

- When you press a key, the top part of the case hits the bottom part of the case, creating metal resonance.

- The keyboard comes with silicon pads to try to solve this issue, but it doesn't completely remove the issue.

- I added tape to the screw points that connect the case, separating the case very slightly to solve this problem, as shown in image 2.

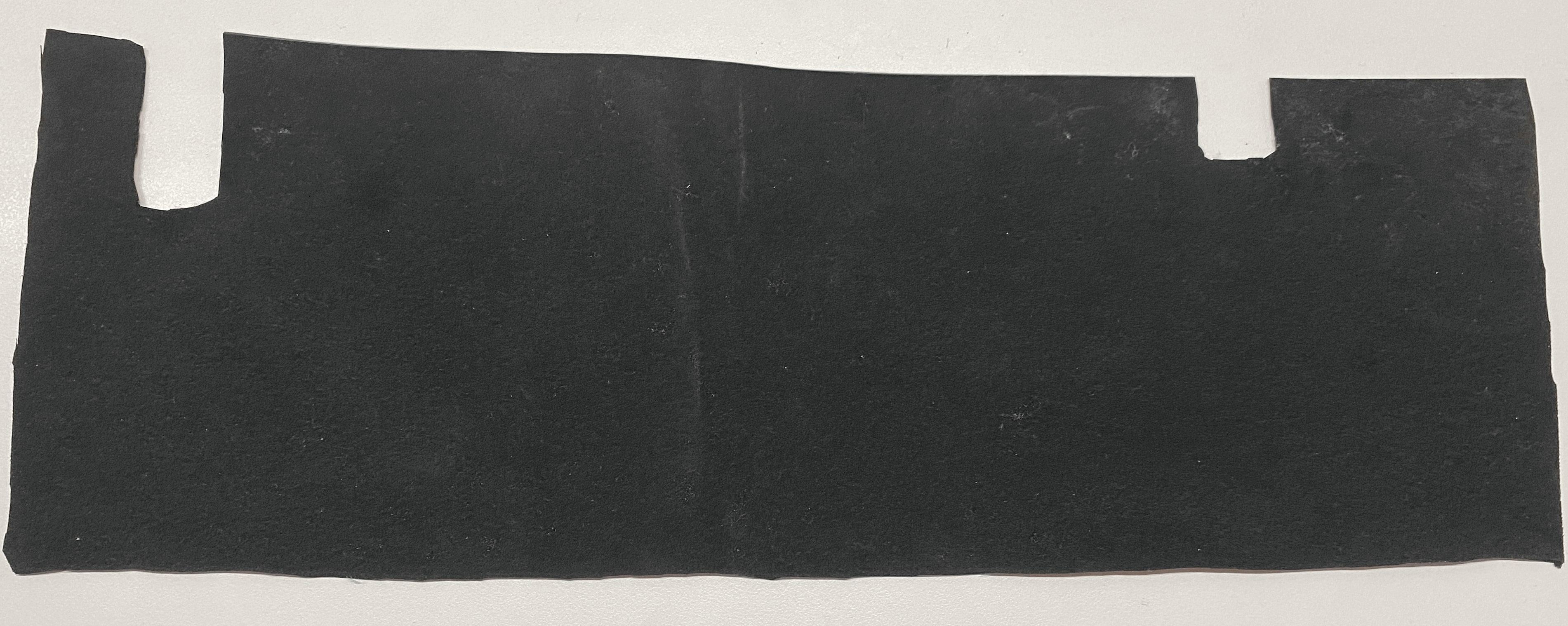

The polyfill layer:

- As the case is thick solid aluminum, when you press a key, due to the empty space between the PCB and the case, the sound bounces around in the case, causing high-pitched echoing.

- I initially used a Poron foam cutout to solve this issue, as seen in image 3, but it damps the sound of the keyboard too much and makes the keyboard flex less when pressed.

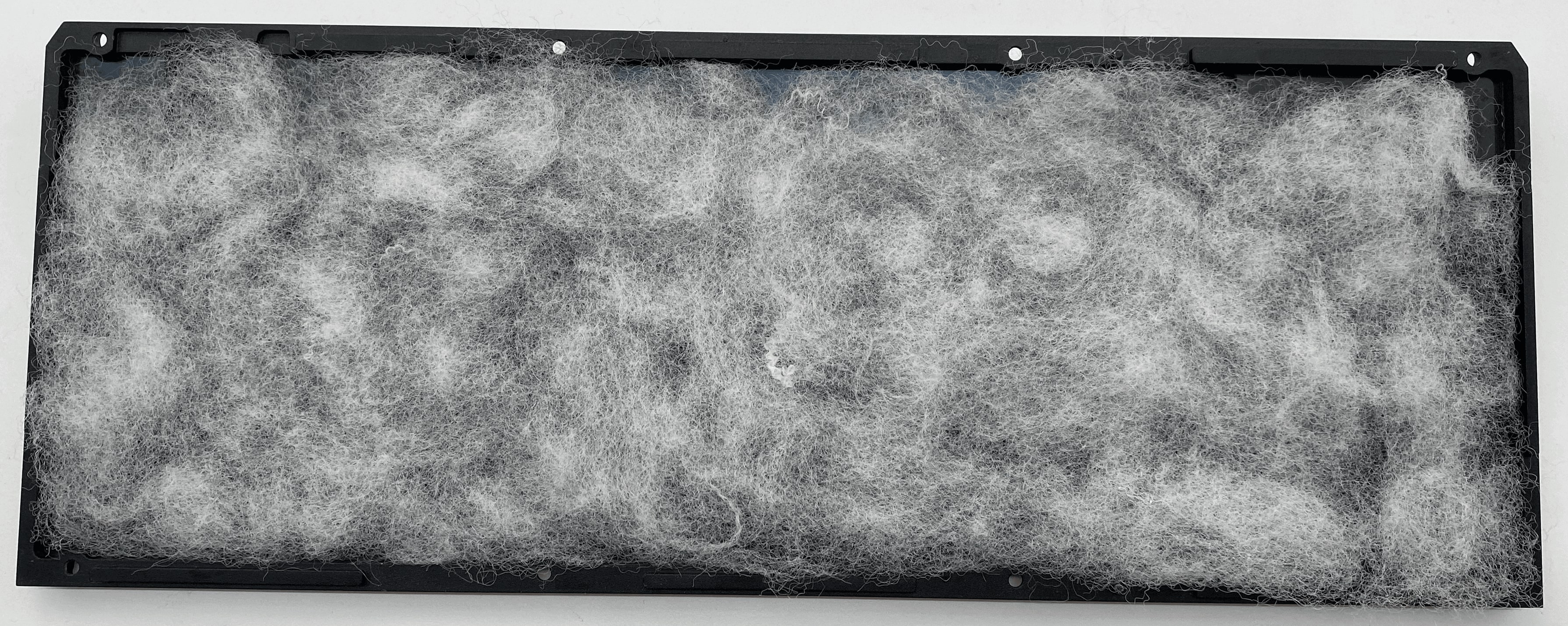

- Due to cotton having the risk of static electricity, I used polyfill, which allows the keyboard to still flex downwards while solving the echoing problem at the same time. Image 4 shows the case with the polyfill.

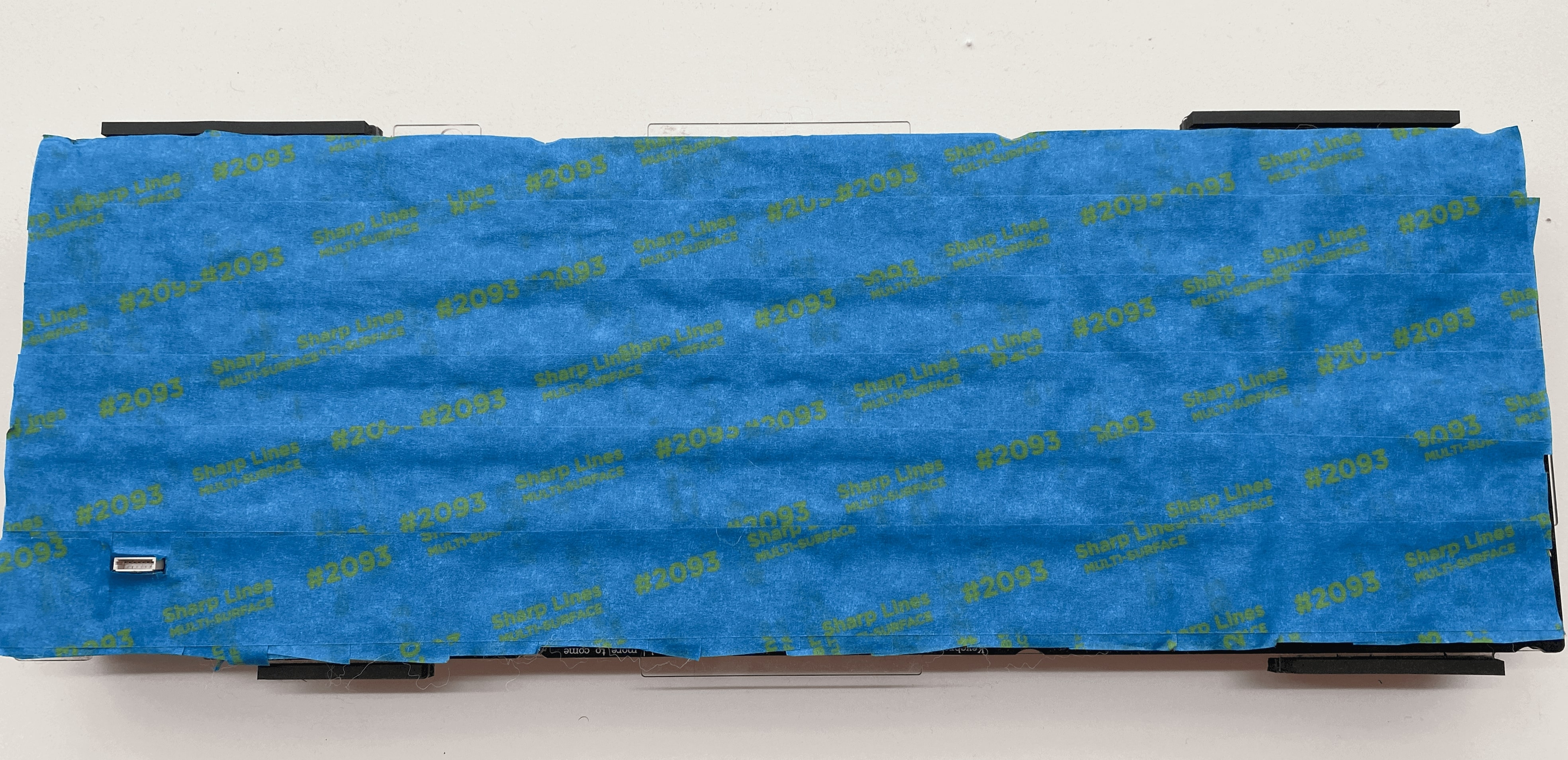

Tape mod:

- By applying layers of tape on the back of the PCB, it increases the volume and deepens the sound of a keypress.

- It is a very well-known mod across the mechanical keyboard community, and I used 4 layers of painter's tape for the mod, seen in image 5.

- It works by reflecting the (deeper) longer wavelength sound upwards and letting the (higher) shorter wavelength sound go through the tape.

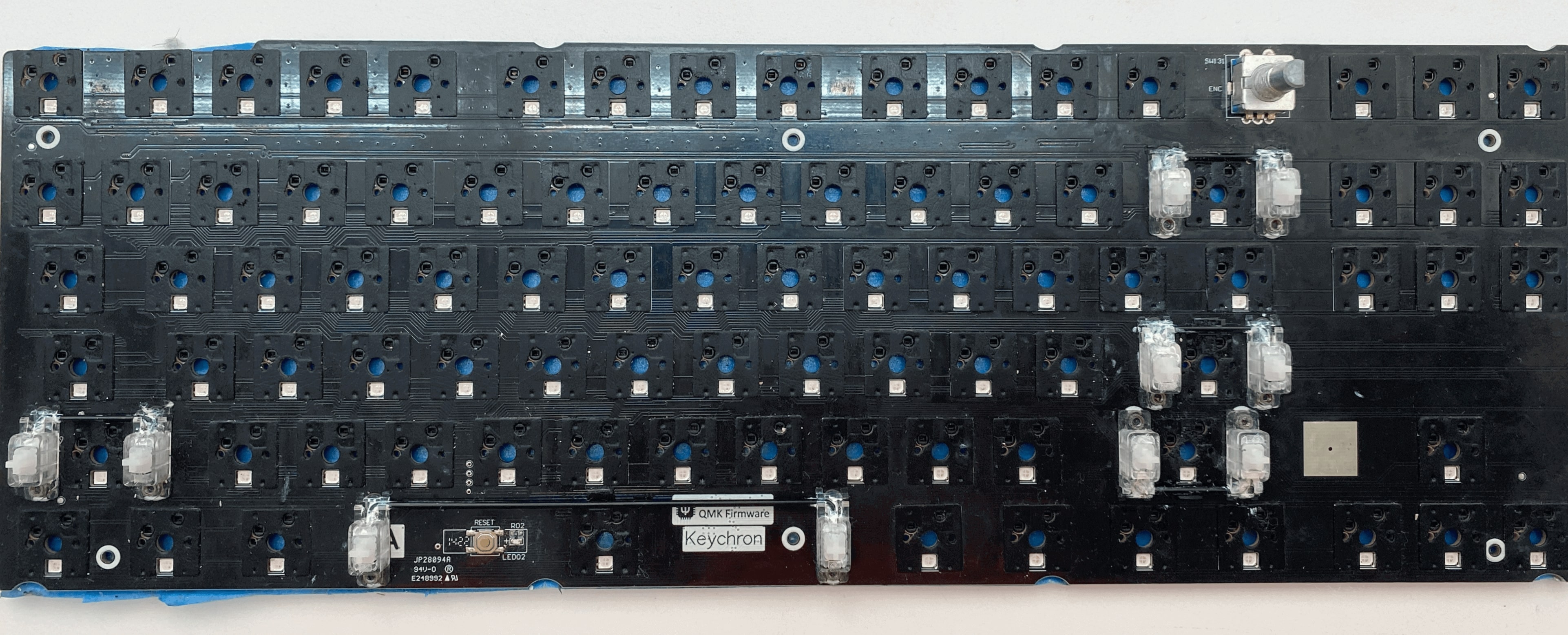

The PCB:

- Two mods are done on the PCB, PE foam switch pads and Staebies stabilizers are added onto the PCB. The mods can be seen in image 6.

- PE Foam Mod:

- PE foam switch pads are stuck onto the PCB.

- PE foam removes extreme high and low frequencies, making the keyboard sound more uniform.

- It solves the issue of the key presses sounding different if the keys are at different locations on the board.

- Stabilizers:

- Staebies stabilizers are made with polycarbonate plastic, which produces deep frequencies when hit by the keycap.

- The stems used by the stabilizers are made with POM plastic, which produces high-frequency sounds, so I put Poron pads under the POM stem to absorb the sound it makes when it hits the PCB.

- Staebies also have a unique design that makes rattle nearly impossible on the stabilizer. I lubed the stem with Krytox 205g0, which provides perfect consistency for small moving parts when thinned out.

- I then used Krytox XHT-BDX lube on the stabilizer wires. Its thick consistency further prevents rattling of the stabilizer wires, which is caused by the stabilizer wires not hitting the stem at the same time. The thick lube dampens the sound when the stem is hit.

The plate:

- Initially, the keyboard came with an aluminum plate. This is not desired as it produced high-pitched sounds when the plate is hit by the switches.

- I bought a polycarbonate plate instead, as seen in image 7. It increases flex due to it being a soft plastic, and it produces a deep sound when it is hit by the switches.

- The plate initially didn't fit the keyboard, so I used a nail file to trim down some plastic to make it fit the keyboard.

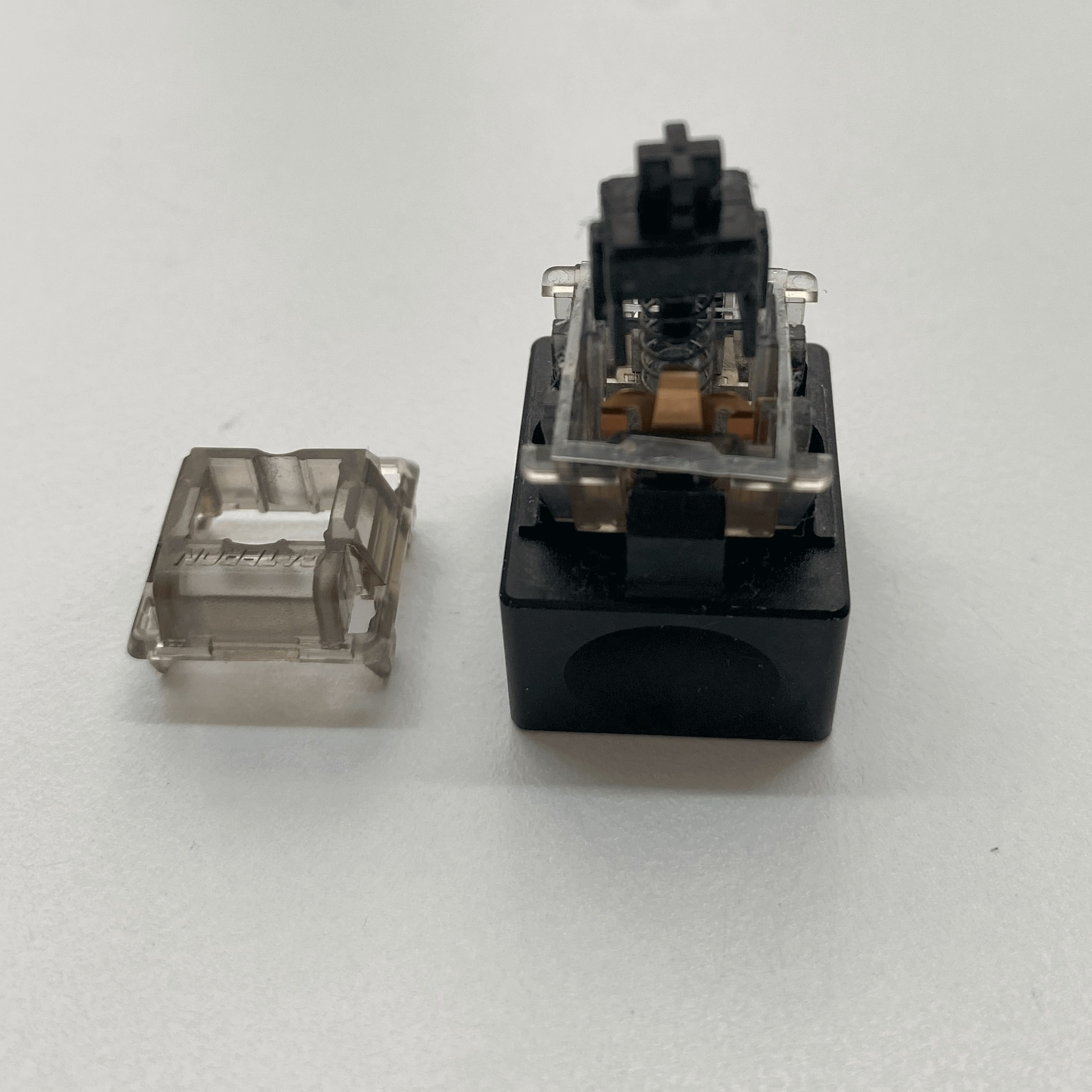

The switches:

- The switches I used are the Gateron black ink v2 switches, seen in image 8. The casing is made of polycarbonate, which again produces a deep-pitched sound.

- As I primarily use the keyboard for typing, I used the original 80g springs for additional damping, to stop finger pain from prolonged usage.

- Each switch is lubed with Krytox 205g0 for a smoother key press and filmed to keep the switch stem more stable, reducing wobbling when pressed, improving typing accuracy.

- The spring and the lubed switches can be seen in image 9.

The keycaps and sound control knob:

- There are only two types of plastic generally available for keycaps, ABS or PBT plastic. ABS produces higher frequency sound waves than PBT and corrodes faster, but they are easier to manufacture and allow for more colors.

- What also affects the sound is the thickness and height of the keycaps; thicker and higher keycaps produce deeper sound waves.

- High-quality thick PBT keycaps are extremely expensive, so I went for Drop MT3 high profile ABS retro keycaps. These were extremely thick and produced deep sound waves even though they are made of ABS.

- During a Drop event, we managed to get a buy one, get one free coupon, which allowed me and a friend to get two sets of MT3 keycaps for the price of one.

- The sound control knob is an old guitar knob that fits the colorway of the keycaps. Both of these components can be seen in image 1.