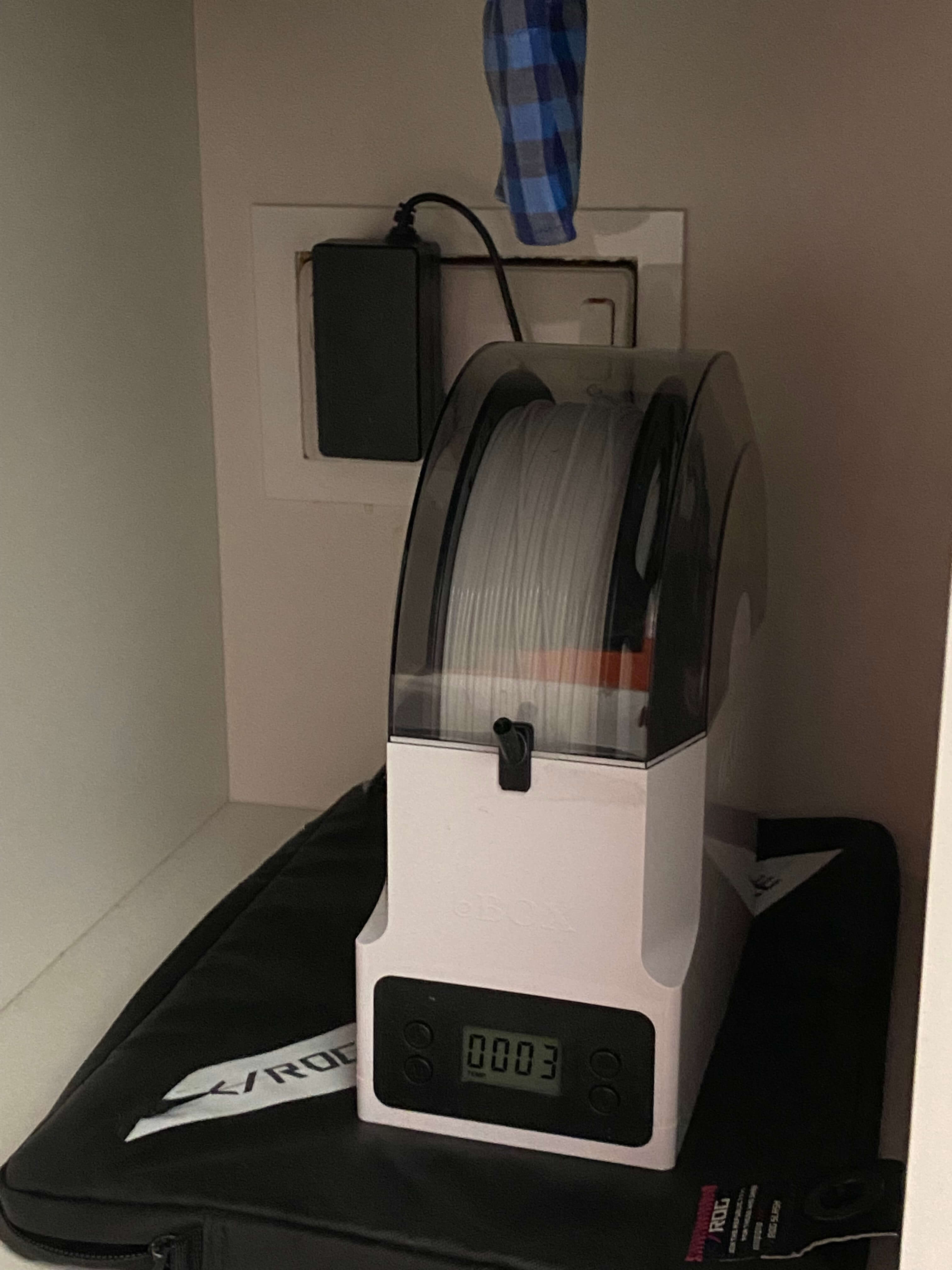

My 3D printing setup in my year 1 dorm at University of York, which I sold on Ebay at the end of the year.

The setup consist of:

- Bambulab A1 mini 3d printer

- Esun ebox lite dryer

- 3D printed parts

- Custom length PTFE bowden tubes

Why the A1 mini?

- At £155 new, the A1 mini is a no brainer to have.

- It is capable, user friendly, with ability to monitor prints via the on board camera, and have good resell value.

- It allows me to print the materials that I wanted, which is PLA, TPU and PETG.

What is the ebox lite dryer for?

- It is essensial for filament to be dry before printing to achieve good printing quality, especially for materials like TPU and PETG.

- If the filament is not dry, the moisture in the filament will turn into steam when printing, causing issues like stringing and inconsitent extrusion, affecting print quality.

- The ebox lite can reach a chamber temperature of 55°C, which is enough for the materials I want to print, it is purchased from Ebay for £15.

- The dryer is very noisy, so I put it in the closet as seen in image 2 when I am in the room.

What 3D printed parts are in the setup?

- For the printer:

- In image 1, you can see the purge bin, cable guide sleeve and cable clips are made for the printer.

- When the A1 mini finish undergoing dynamic flow calibration or filament change, a small blob of plastic is ejected, the bin catches it.

- The cable sleevs and cable clips are for aesthetic.

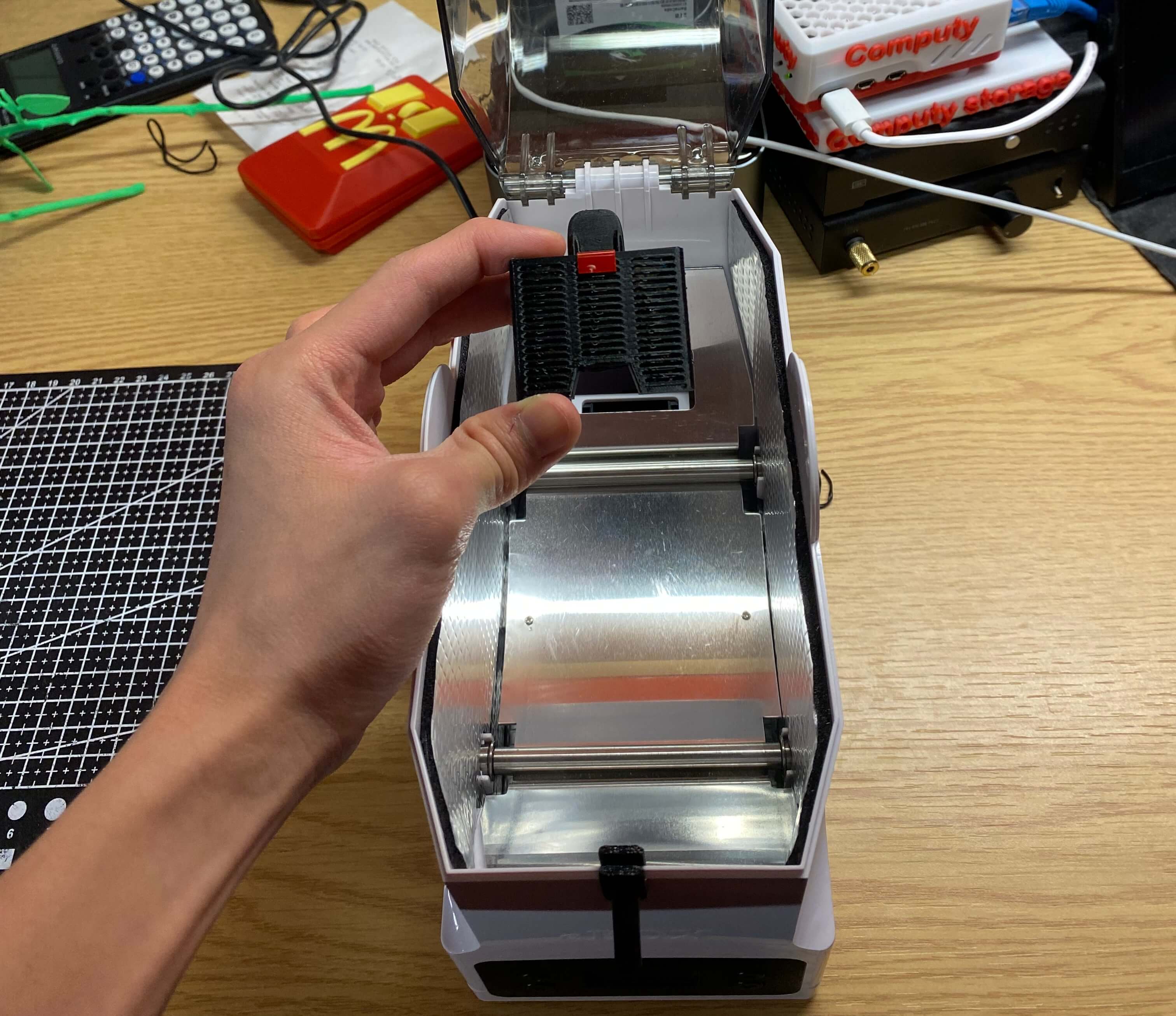

- For the dryer:

- In image 3, you can see the desiccent box and the PTFE tube coupler, both printed in PETG

- The coupler allows the PTFE tube from the printer be docked onto the dryer, allowing drying while printing.

- In image 4, a desiccant box filled with color-changing desiccant absorbs moisture released from the filament, preventing it from being trapped in the chamber, the desiccant turns green when there is moisture, which then by microwaving it, the desiccant can be reused.

Custom length PTFE bowden tubes:

- The stock PTFE tubes is too short to allow for the printer to print from the dryer.

- I spent £2 to buy 2 meters of PTFE tubes from aliexpress, which I cutted it to perfect length.

- The extra PTFE tubing can be seen in image 5

Why and how did I sold my setup?

- Towards the end of the year, in the University of York makerlab "Yorcreate", they purchased a Bambulab p1s printer, which allowed me to use my own cheap 1.75mm filament on a bigger and superior printer.

- Student storage over the summer is expensive, and the printer doesn't lose much value in the used market.

- I listed and sold the printer for £180, I then repacked the entire printer extra items requested by the buyer in its original box, which at the end is close to 15kg.

- The reason the printer was sold for £180 is because of a cracked printhead, allowing me to have an extra replacement printhead from a warranty claim.

- The filament dryer was sold for £10

- The packed printer can be seen in image 6